Planning a Successful Delivery — Oversized Custom Windows

“The windows are coming! I need a helicopter!”

Right now, we’re in the process of delivering a good-sized order of oversized, custom-built Bronze-clad Black Walnut windows and doors to a luxury home on the shores of Lake Tahoe. The secluded waterfront lots in Tahoe are difficult to get into, with regulations protecting the shoreline, a notoriously short building season, narrow roads and heavily-treed properties. It takes detailed planning and a few creative ideas to get massive custom windows and doors into a remote location like this.

In this instance, it took a helicopter. (More on that later.)

Getting oversized custom windows from the factory floor to the rough opening at the job site is a collaborative process. Our part is to align the window agenda to the entire project’s agenda, looking for potential challenges we can help solve before they become a problem.

Delivery day should be fairly painless, if you start planning the logistics all the way from the design stage. Without that preparation, it can be very costly — not just in dollars but in damaged reputations.

Here are some of the questions we explored with the design team, which allowed everyone to plan for a successful BIG glass delivery to a beautiful but rather inaccessible and remote job site.

Working Out the Logistics of Delivering Oversized Windows & Doors to Remote Building Locations

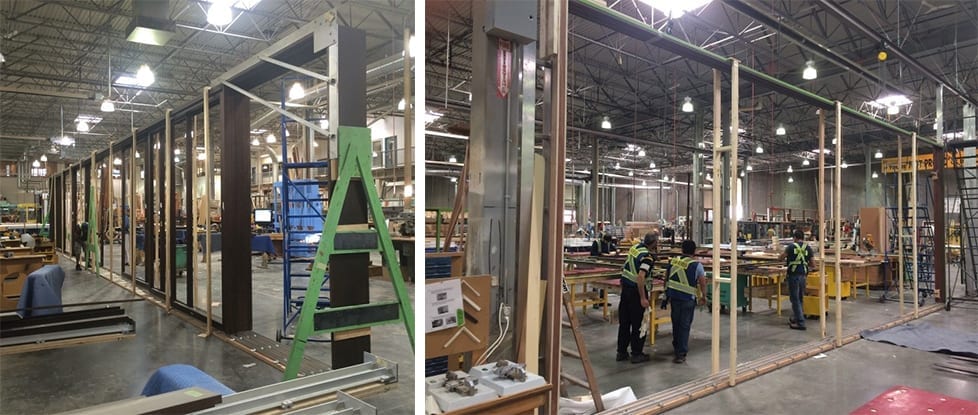

Long before we started manufacturing the windows for the Tahoe project, we were talking to the architect and contractor about the practicalities of fabricating the designs as drawn. (Just because we can build something as drawn doesn’t necessarily mean we should!)

Looking at the conceptual designs, we started by talking about the proposed size and weight of the larger window and door units. Clearly, the logistics of getting the huge windows and doors to the openings needed to be discussed before we even started building the windows. Here’s what we looked at:

1. Can a trailer access the job site?

Tahoe, much like Pebble Beach, Malibu, The Yellowstone Club in Montana or downtown Manhattan, isn’t a place you just drive into. Roads are narrow, turning circles are tight or non-existent and access may be restricted to certain hours or certain vehicle sizes.

2. Will the oversized custom windows fit onto the trailer?

Sometimes, oversized windows can be shipped knocked down and assembled on site. Other times, we help devise different solutions. It’s a question of learning what’s possible on the contractor’s side.

3. Once the trailer is on the site, what is involved in getting the windows off the trailer?

Just because it’s easy for us to load it, doesn’t mean it’s going to be easy for the Contractor to unload it.

At the factory, we’re able to load on a flat surface; the loading dock and trailer are the same height. For us, it’s relatively easy to handle. Lots of manpower, shop floor lift equipment, no wind or rain, just slide the door onto the trailer. Easy, right?

68 foot wide Double Pocket Lift and Slide Doors

The contractor typically will not have the same advantages, especially if it’s a delivery direct to the job site. To make it work, we have conversations about the details of the delivery before building the windows & doors.

4. Does it make sense for the contractor to build a temporary unloading platform?

A platform built to the same height as the trailer offers an even surface to slide the windows onto. It also provides a working surface where the lifting straps and spider lift suction cups can be securely attached prior to hoisting.

Having discussed each opening prior to fabricating, weights and sizes were reviewed and the appropriate lift equipment was identified. For this project, the contractor had time to verify that the equipment he would need was available and could also access the site.

“Any design team knows that decisions can be like dominoes – you move one into place and three others might tip over. Tipping over dominoes made of drawings on paper is better than tipping over dominoes made of concrete — or bronze-clad Black Walnut.”

5. What are the site-specific challenges?

Tahoe code prohibits heavy equipment on the actual shoreline so the entire lakefront elevation is typically off-limits to lift equipment such as a GradeAll or forklift.

With this particular job, the roof would be on by the time the windows were scheduled to arrive. The roof height was too high to crane over to the lakefront side. There are construction cranes with enough reach for the height and distance but these cranes were too large to get onto the job site.

Being waterfront in Lake Tahoe, the glass has to be low-reflectivity to meet code. That stuff isn’t cheap so careful planning and handling was all the more important. Any breakage could mean delays to the construction schedule.

Tahoe also has a notoriously limited building season. Contractors are under immense pressure to have the building closed up before the snow hits. Missing that deadline is not an option. Like any team member, it’s our job to understand and coordinate with the contractor’s agenda with these pressures and constraints in mind.

14’ Tall Lift & Slide Door

“Just because we can build something as drawn doesn’t necessarily mean we should. We’re working for the success of the entire design team, which means looking for potential challenges and working to solve them before they become a problem.”

Catching and Solving Potential Problems Early

We clarified the crane requirements. It turned out that the spider lift had a maximum capacity of 1400lbs. Since we were still in the design phase, we had the opportunity to revisit each opening that was in the 1400lb + weight category and devise a solution that met the architect’s design intent and the contractors handling requirements.

The Great Room window wall was the biggest challenge. We couldn’t change anything without disrupting the design intent and sight lines, which in turn disrupted alignment to adjacent openings and the datum line across the entire elevation. The Great Room window wall was the primary feature window wall in the entire project – on the lake side and bang in the middle of the “No Heavy Equipment” zone. The eventual answer: lift it in by helicopter.

Each solution was discussed with the homeowner and interior designer, further tweaks were made and a complete solution arrived at. Everyone knew what they were getting and why. The owner approved the cost of the helicopter rather than change the window wall design.

“The core responsibility of a window fabricator in the luxury niche isn’t to sell windows. It is to protect the best interests of the project. Do that first, foremost and always and clients will buy from you. It’s not about windows and it’s not about “selling”. It’s about contributing the most we can to the success of the project overall. That’s how we all win.”

The End Result

The detailed conversations led to a series of solutions that included some of the large trapezoid clerestory windows shipping with the glass loose to make the weight more manageable for the site conditions and available equipment. Knowing that some glass will ship loose, we could talk about the on-site glazing process and think through the scaffolding and lift equipment being in the right place when it came time to glaze. These considerations saved time and money in the setup and take-down. Maneuvering around the overhangs of the roof was also taken into consideration.

“Imagine if the design team had not gone through the detailed discussions on size, weight, site access, equipment. If the truck just showed up and now you have a crew standing around costing a fortune per hour wondering what the heck they do next.”

With these conversations taking place in the design phase, the architect, contractor and window fabricator (along with the project engineers, interior designers and homeowners) are able to coordinate solutions that met everyone’s agenda. The fabrication of the custom architectural windows went ahead based on these solutions. The requirements to successfully deliver the windows were understood by everyone and the contractor had time to work through all the logistics and permits needed to pull it off.

Talking about windows isn’t enough. Conversations should eliminate assumptions that cost time and money to deal with later.

Oversized Windows in Remote Luxury Homes #dynamicwindows #architecture