Finishing Bronze:

Combining Traditional Techniques with New Technologies to Refine our Finish on Architectural Bronze Fenestration

Bronze windows and doors add an unmatched level of prestige and individuality to any architectural experience. Beyond its timeless elegance, bronze will also outlast any other architectural metal alloy, and it will not rust or corrode even in high salt exposures. These simple facts make bronze the ideal material for fenestration in any luxury architecture.

However, the timeless elegance of bronze is also augmented by its changeable nature, which may sound like a contradiction. Contrary to other materials, bronze actually has the capacity to transform over time, due to the natural patination and oxidation of the alloy through exposure to its immediate environment. To learn more about this process, see our previous blog on this topic here.

At Dynamic Fenestration, we’ve worked hard to refine our finishing procedure for bronze, especially for exterior applications, and we’ve developed an approach through a stain application that both enhances the beauty of bronze while also mitigating oxidation. This approach actually stabilizes the aesthetic of the finish and essentially offers the best of both worlds—combining traditional finishing techniques with new finishing technologies.

Patina

Patina is an Italian word that refers to a thin, surface layer that forms on various materials as they age. It is a completely natural process as the material is exposed to chemicals or acids, whether occurring in the natural environment or purposefully applied.

Patina on bronze is a result of oxidation and can develop a green or brown hue, depending on various factors and their levels of exposure. For some, this creates a desirable finish. For others, the instability causes concern.

However, the bronze patina will change over time, depending on several variables, including the composition of the bronze, other protective treatments, weather, location, pollutants, adjacent materials, and maintenance and cleaning.

Understanding a little about the art and science of bronze patinas can help you select the ideal finish, for both longevity and appearance. Here are a few guidelines for working with architectural bronze from our experience with windows and doors.

Natural Patina

First, it is important to remember that architectural bronze is a metal alloy that consists of copper, lead and zinc with trace elements of iron (approx. 0.35%). The level of copper determines the high resistance to corrosion, and the level of zinc contributes to the hardness and tensile strength of the material. As an alloy, architectural bronze will change at a different rate than pure copper.

Second, we remind you that even completely natural patinas contain various chemical compounds, including oxides, carbonates, and sulfates which naturally form on the surface of the metal.

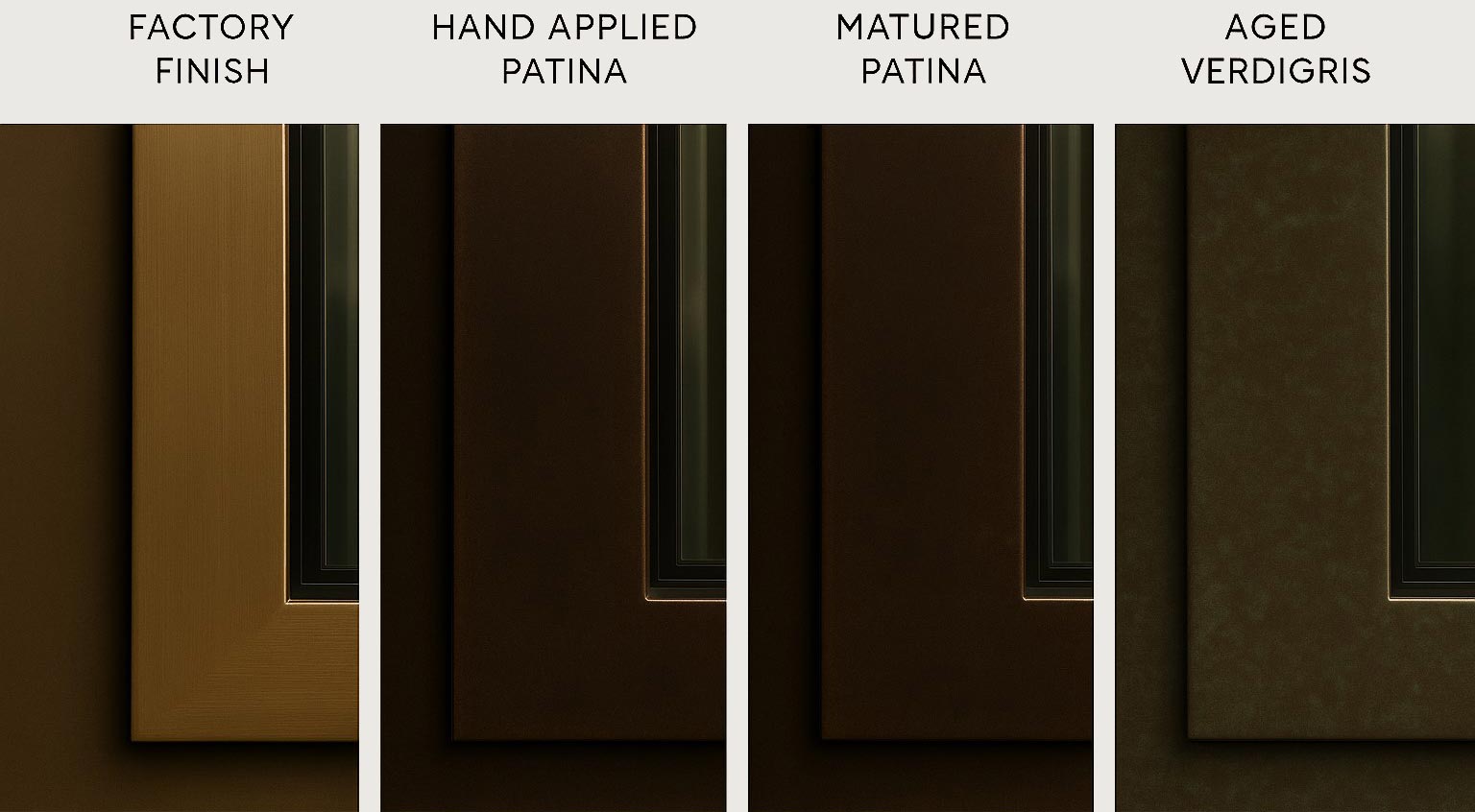

However, if the patina is left to age without any intervention, you must expect to have a range of finishes, textures, and colors. As well, this range of difference will vary over the years, going from shiny to dull and raw, from golden brown to black, and eventually to different shades of green. The percentage of copper in the material will be a critical factor to the rate of change and resulting colors. Copper roofs and gutters are good examples of patination in action.

As well, the rate of change or finish of the patina will depend on the environment in which the bronze is placed—whether the air is clean or polluted, whether the humidity is high or low, whether exposed to salt or not, and other similar factors. For example, natural patinas will develop faster in coastal and marine environments than inland locations.

If a completely natural patina is your desired aesthetic, we applaud your inclination, yet we strongly suggest that you consider another option, which is our dual-purpose finish of a sealed, stable factory patina that is specially designed for bronze fenestration in exterior applications. We are confident in our tried-and-true approach.

Hand-Applied Patina

Due to the unpredictability of natural patina finishes, we are in favor of a hand-applied patina. We are convinced that the beauty and durability of bronze can also be created and enhanced through handcrafted finishing techniques and advanced sealer coatings. These factory finish patinas are providing beneficial options in the world of architectural bronze fenestration.

In some circles, a light patina finish on bronze is a growing trend. However, it wasn’t long ago that a much darker patina was generally preferred, which was often referred to as “Oil Rubbed Bronze.” This darker finish was highly valued due to its mottled lustre and naturally aged appearance, which was full of character and resonance, signs of a well lived life.

However, new application techniques and new welding alloys have changed the aesthetic outcomes of light patinas on bronze. Now, there are fewer inherent pitfalls that must be addressed in order to decide on the finish, leaving the final choice more clearly in the realm of aesthetic preference.

Some light patina finishes can appear too consistent, or in some cases cloud the deep luster of the bronze itself, which for many peoples is its most desirable feature. The mottled effect of a naturally aged bronze surface, encouraged with a medium patina, is often more preferable and blends more consistently with other design elements such as natural stone or wood. The inherent inconsistencies of the material become a valued attribute of the aesthetic, giving the finish a more organic feel—the perfection of imperfections, if you like.

When our clients choose architectural bronze for their fenestration, we try our best to discuss all of these factors as they make decisions about their patina of choice. Since bronze fenestration will likely be around for a very long time, outlasting all of us, even to our grandchildren’s grandchildren, it is best to get it right.

Maintenance

With any factory finish on architectural bronze, some maintenance is necessary.

Even the best patina finishes on bronze will change over time, ideally assuming a desirable aesthetic with a subtle mottled character. In the end, some change is inevitable, though the range is mitigated significantly in comparison to a natural patina finish. So, if the design intent is to preserve something close to the original patina appearance, it will require some maintenance, which will sufficiently slow the natural processes and prevent substantial change.

Conclusion

Architectural bronze windows and doors offer timeless elegance and premium performance. As a living material, your bronze will undergo inevitable change throughout the aging process as it interacts with its environment, yet we have developed a finishing practice that still embraces the organic charm of bronze while also mitigating its evolution and stabilizing its patina.

For those who choose architectural bronze for the fenestration on their next project, we are unreserved in our recommendation of a hand-applied patina finish, and we would be happy to guide you in a discussion about your preferences and expectations of bronze, and how to ensure that the final product aligns with your vision.

Architectural bronze delivers excellent performance, thanks to the protective patina that stabilizes the metal alloy and enriches its appearance, offering an evolving look that adds historical and luxurious charm to any project. Understanding the unique behaviour of this material will help to safeguard the best possible outcome for your experience with it.