Will My Bronze Fenestration Turn Green?

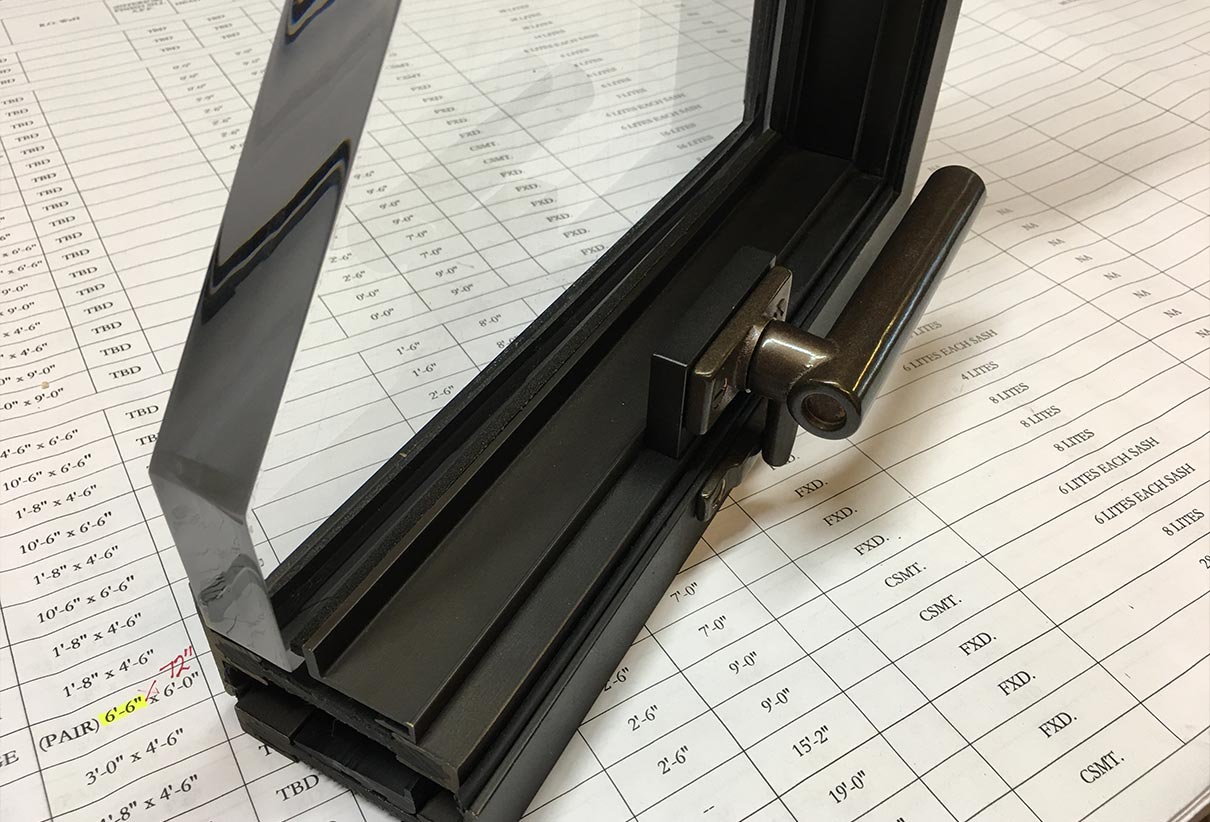

That’s the number one question we get about bronze fenestration. Whether it’s thermally broken Bronze-Arte or Bronze Clad, people want to know if this brilliant metal will eventually turn green.

We’ve referred to this phenomenon before (here, here, and here), but a more detailed explanation has proven helpful for architects and builders that are looking to manage client expectations before investing in architectural bronze fenestration.

The green patina on bronze is natural—but not inevitable

Nature will take its course: lichen can encroach on exterior stone, moss can grow on a slate roof, marble can discolor and stain, and yes, architectural bronze develops patina.

Due to a natural process called oxidation, architectural bronze will gradually develop a patina over time if left to its own devices. Oxidation leads to patination, which is the development of the visible patina that has been the aesthetic allure of bronze for millennia.

The patination of bronze is the inevitable result of exposure to humidity, moisture and contaminants in the air such as salt spray from the ocean or pollution from urban traffic. In many instances, the patina takes on a brown tone, often complementing the factory-applied patination. In fewer instances, however, the patina develops a greenish color. While the brown patination occurs in less humid environments with lower levels of pollution, the green color develops with higher humidity, moisture, salt and sulphur dioxide—and green, for most people, is what they wish to avoid.

The good news is that the green patina on bronze can be mitigated.

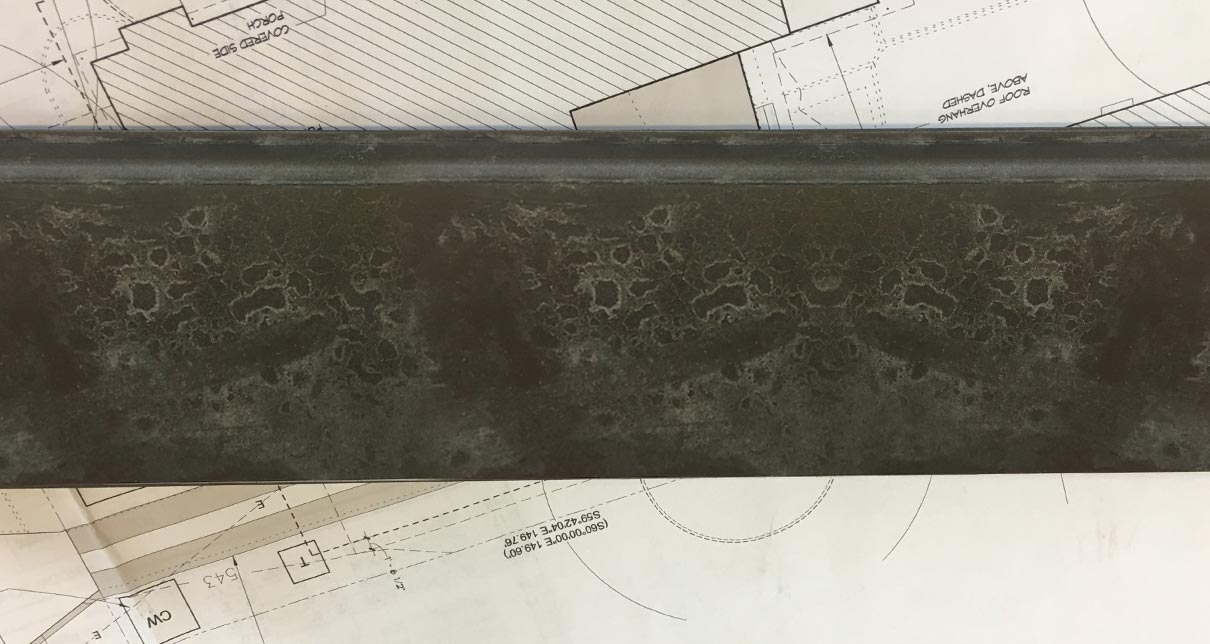

The above slider shows a test piece of bronze that was left on the Dynamic Fenestration roof for 12 years in full weather exposure. Other than some dirt build-up, you can see there’s no rust and no obvious corrosion. The slider shows before wiping the dirt off and then after.

Patination isn’t corrosion

Our clients invest in bronze fenestration for several reasons, but the primary one is that architectural bronze doesn’t rust. Period. Full stop. It’s also one of the very few surfaces that looks better the longer it’s in place.

If patination isn’t rust and isn’t corrosion, what is it? It’s a chemical reaction of the bronze to its environment. The patina is actually a protective layer on the surface of the bronze, which shields the alloy beneath. This process is similar to the patination of copper roofs and gutters.

In fact, it is the presence of copper in the bronze that causes a primary reaction with oxygen, water, and carbon dioxide from the atmosphere. This reaction forms copper oxide (CuO) and copper carbonate (CuCO₃), so the patina consists mainly of basic copper carbonate (Cu₂CO₃(OH)₂), also known as malachite. Over time, this green layer becomes more pronounced as the reactions continue, which brings up the question of mitigation.

Maintaining architectural bronze fenestration

Patinas are actually a very desirable aesthetic, delivering a natural, organic materiality that cannot be replicated with a painted finish. As with many architectural details, patinas are subtle and nuanced, but also powerfully evocative.

In most cases, at Dynamic, we work hard to pre-age our bronze, applying a factory patina finish to jump start the desired aesthetic. Once the bronze finish is perfected, we typically apply a specialized sealer coat over top. This protects the bronze surface from the environmental elements that cause patination. The sealer coat is a flat sheen and completely transparent, therefore you can’t see it and it doesn’t change the aesthetic of your patina finish. But it does mitigate further patination.

Of course, the sealer coat will break down over time, and that process will occur more quickly on high-exposure elevations. However, additional sealer coats can be brush applied on site to preserve the protective function. A paint finish is different: once it has started to fail, you cannot re-apply. So there is a reduced maintenance story to bronze fenestration as well.

Remember that architectural bronze fenestration can be painted, just like steel or aluminum. It doesn’t have to come with a patina finish.

Mitigation and maintenance

Sealer Coat: Applying a protective sealant or coating to the surface of the bronze can help mitigate oxidation and slow down the formation of the green patina. Clear lacquers or wax coatings specifically designed for metal surfaces can be applied to create a barrier against moisture and oxygen.

Regular Cleaning: Regular cleaning and maintenance of bronze windows can help remove dirt, debris, and pollutants that contribute to oxidation. A mild soap or detergent with water can be used to gently clean the surface. Harsh abrasives or chemicals should be avoided because they could damage the bronze.

Polishing: Periodic polishing of bronze windows with a specialized metal polish can also help remove oxidation and restore the original luster of the bronze. There are specific wax products for bronze cleaning. It is critical to follow the manufacturer’s instructions and use a soft cloth to avoid scratching the surface. It’s not rocket science and you don’t need a hazmat suit, just some elbow grease in a thoughtful manner.

Protective Measures: During installation, precautions should be taken to protect bronze fenestration from prolonged exposure to moisture and corrosive elements. Proper flashing, sealing, and drainage systems should be implemented to prevent water infiltration and minimize the risk of oxidation.

Periodic Inspection: Regular inspections should be conducted to identify and address early signs of wear or damage, which can help prolong the life of the bronze fenestration. When areas of accelerated patination appear, that’s the time to clean and protect the patina. Look for physical wear and tear. For example, wind-blown sand can cause physical abrasion to bronze surfaces, leading to a rougher texture and potentially exposing fresh metal to the elements, which can then oxidize and patinate more rapidly.

These maintenance and mitigation measures do not require any magical incantations, and you certainly don’t need to hire an alchemist in a tin foil hat. On the contrary, hopefully these simple guidelines will become common sense as the causes of patination are understood.