Vacuum Insulated Glass (VIG)

for Luxury Residential Architecture:

An Unbiased Overview

Introduction

Most architects have, by now, heard glowing reports about Vacuum Insulated Glass, also known as VIG. It boasts game-changing thermal performance, ultra-slim lines, and the end of triple glazing. Though the thermal performance of VIGs is not in doubt, there are definite aesthetic questions remaining that may outweigh this performance factor. We are asking the basic question, What is keeping VIG from being more widely specified by architects in luxury homes?

VIGs are not actually new, but in the past two years we’ve seen incredible innovation and improvement for this product. So, what has changed, and what do you need to know before diving into this latest glazing innovation?

Below is a factual, balanced summary tailored for architects designing luxury homes. In this overview, we have focused on three key factors: performance data, application scenarios, and current (2025) aesthetic realities.

As well, architects should be aware that not all VIGs are alike. There are a wide variety of manufacturers and exact specifications, performance, and aesthetics do vary from supplier to supplier.

In addition, the rate of innovation is significant in this industry, so details and published data quickly become redundant. Even six months is a long time in VIG product development.

Vacuum Insulated Glass Definition

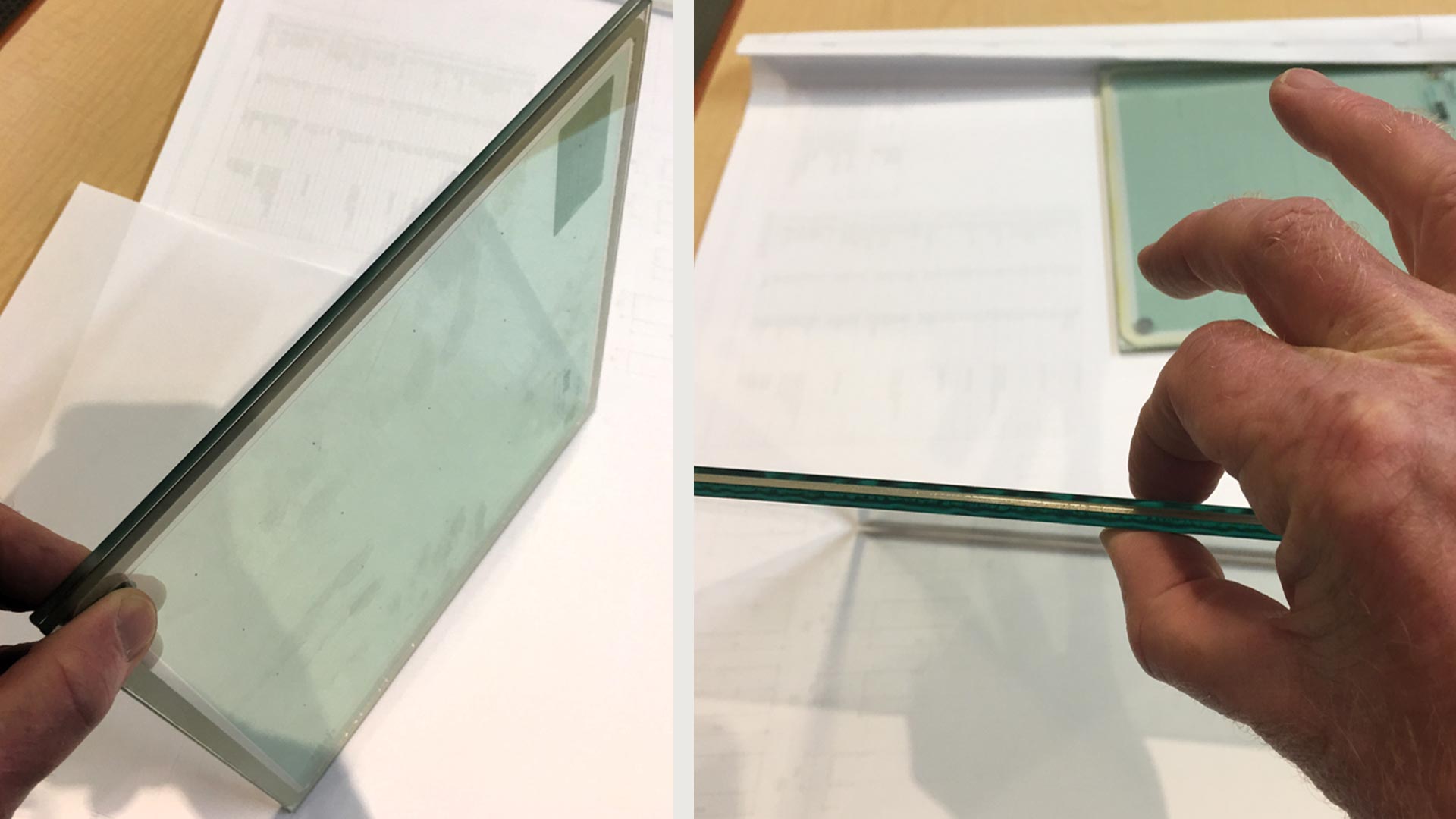

Vacuum Insulated Glass consists of two panes of glass separated by a narrow vacuum gap, typically maintained by micro-support pillars and sealed at the edges. The vacuum eliminates conductive and convective heat transfer, making the unit highly insulating and very narrow compared to a conventional dual or triple pane insulated glass unit (IGU).

Pros & Cons of Vacuum Insulated Glass

| VIG Pros | vig Cons |

|---|---|

Exceptional Thermal Performance

| Visible Micro-Pillars

|

Ultra-Slim Profile

| Edge Seals

|

Acoustic Insulation

| Exterior Condensation

|

Durability

| Cost

|

Aesthetic Preservation

| Size and Shape Limitations

|

Repair and Replacement

|

Specifications: When, Where, and Why

Ideal Applications:

- Heritage and Period Properties: When building codes or conservation officers require preservation of original frames or profiles, VIG can deliver modern insulation while maintaining the original design intent.

- Luxury Homes and Hospitality: Where maximum comfort, energy efficiency, and acoustic control are priorities, and clients are willing to invest in premium solutions.

- Retrofits: For upgrading single glazing without changing existing frames, especially where frame depth is limited.

- High-Performance New Builds: In homes targeting passive house or net-zero energy standards, VIG helps achieve stringent envelope performance. Sustainability and regenerative design narratives indicate that a conversation about VIGs may be appropriate.

Expectation Management:

- Aesthetics: Architects should review mock-ups or samples to assess the visibility of pillars and edge seals, especially for large, unobstructed panes.

- Climate: In climates prone to exterior condensation, client education is important to set expectations. Condensation is not a glass issue but a relative humidity issue, just as it’s always been.

- Budget: Weigh the positives of client experience, high thermal control, sound abatement and comfort against the higher upfront cost. The cost of purchase versus cost of ownership ratio remains a valid exercise in uncovering actual value.

Aesthetic Realities in 2025

- Pillars: Modern VIG uses micro-pillars, typically less than 0.5 mm in diameter, but they are visible in certain lighting or at close range. Determining the degree to which the pillars are “invisible” or intrusive is subjective. They aren’t invisible and to suggest or imply otherwise is disingenuous at best. The pillars are visible if you look for them but remember that the intent is to look through glass, not at glass. It is subjective, so be proactive and manage expectations accordingly.

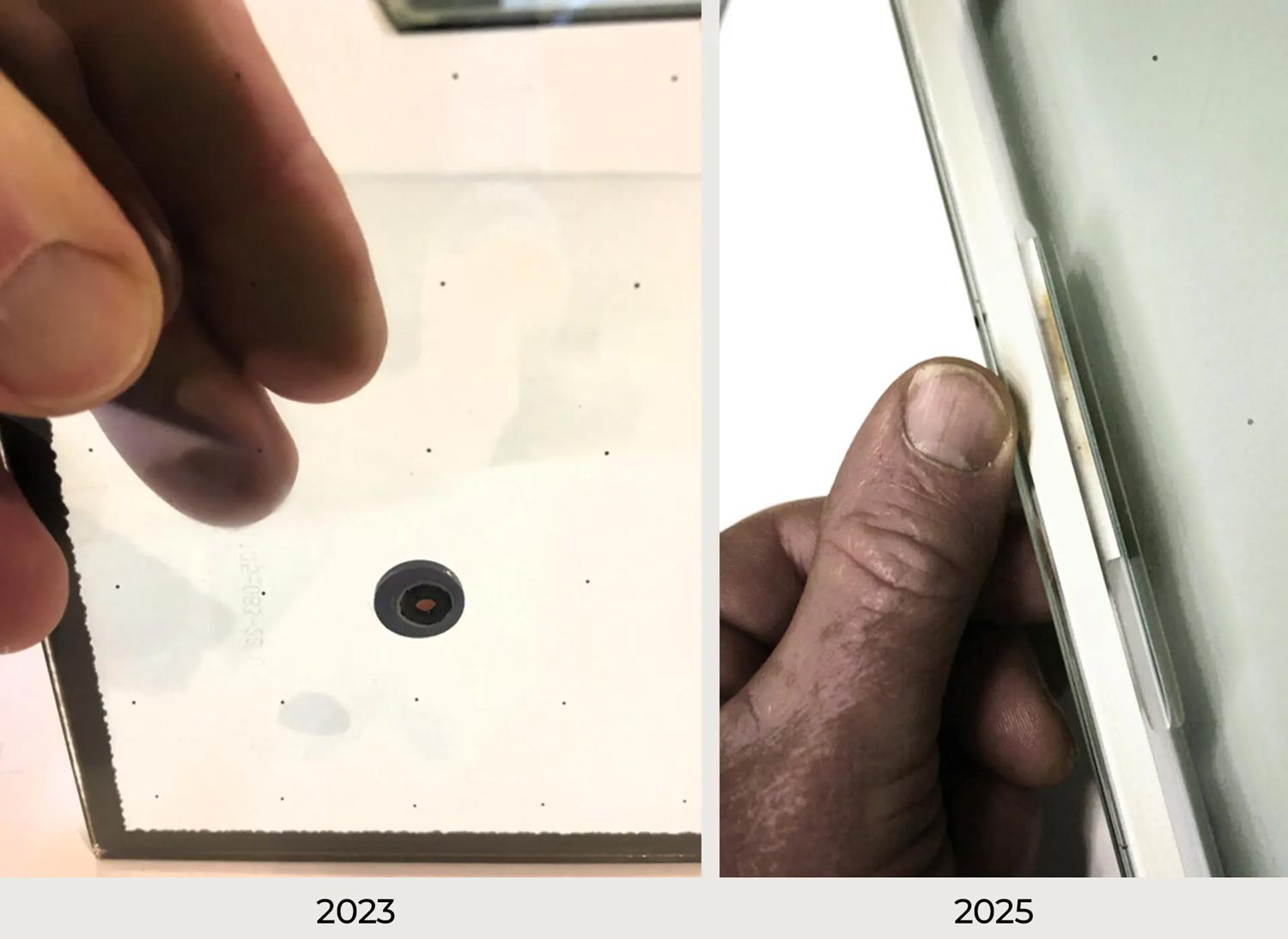

- Vacuum Ports: These have been the Achilles Heel of VIG units until very recently. The port is where the air is drawn out of the VIG to create the vacuum. In the past, they were so visually intrusive that—if we’re being honest—you couldn’t give this stuff away no matter how well it performed. That has improved exponentially if you look at the 2023 and 2025 VIG samples below:

- Edge Seals: Most leading manufacturers now use metallic seals, which are more durable but can create a thin, metallic border around the glass. The seal width varies by manufacturer but is generally wider than standard IGU seals.

- Glass Quality: VIG can incorporate low-iron or ultra-clear glass for premium clarity, and hybrid units can combine VIG with additional panes for enhanced performance or special coatings. Regardless of glass and coatings, the pillars remain a structural necessity, for now.

Summary Table: VIG vs. Conventional IGU

| feature | vig | double glazing | triple glazing |

|---|---|---|---|

U-value (W/m²·K) | ~0.4 | ~1.1–1.3 | ~0.7–0.8 |

Thickness | 6.7–8.3 mm | 24–28 mm | 36–44 mm |

Visible Pillars | Yes (micro, grid pattern) | No | No |

Edge Seal Visibility | Moderate (metallic/glass) | Low | Low |

Weight | Low | Medium | High |

Retrofit Suitability | Excellent (slim, light) | Limited | Poor |

Cost | High | Medium | High |

Conclusion

Vacuum Insulated Glass has evolved and offers architects a powerful tool for delivering high-performance, energy-efficient, and acoustically enhanced glazing in new luxury homes, historical restoration or renovation projects, and luxury hospitality. The unique characteristics of this new technology—its slim profile, visible pillars, vacuum ports, and edge seals—still require careful consideration, particularly in client expectations of the visual aesthetics. The upsides of VIG continues to grow while the downsides recede. VIG will be a game changer in glazing as adoption increases—and adoption is increasing exponentially as the designs improve. Watch this space, folks!